Understanding the Basics of Concrete Grinding and Its Benefits

Concrete grinding is a vital process in the realm of construction and renovation, transforming rough, uneven, or worn concrete surfaces into smooth, aesthetically pleasing, and durable floors. For property owners, contractors, and business operators in Birmingham and beyond, the value of professional concrete grinding cannot be overstated. It not only enhances the appearance of concrete floors but also prolongs their lifespan, reduces maintenance costs, and prepares surfaces for finishing or sealing. If you’re seeking top-tier services, understanding the core principles of concrete grinding, its advantages, and how to select the right provider is essential. For those in Birmingham, the local expertise ensures customized solutions that meet regional standards and project requirements.

What is concrete grinding and how does it work?

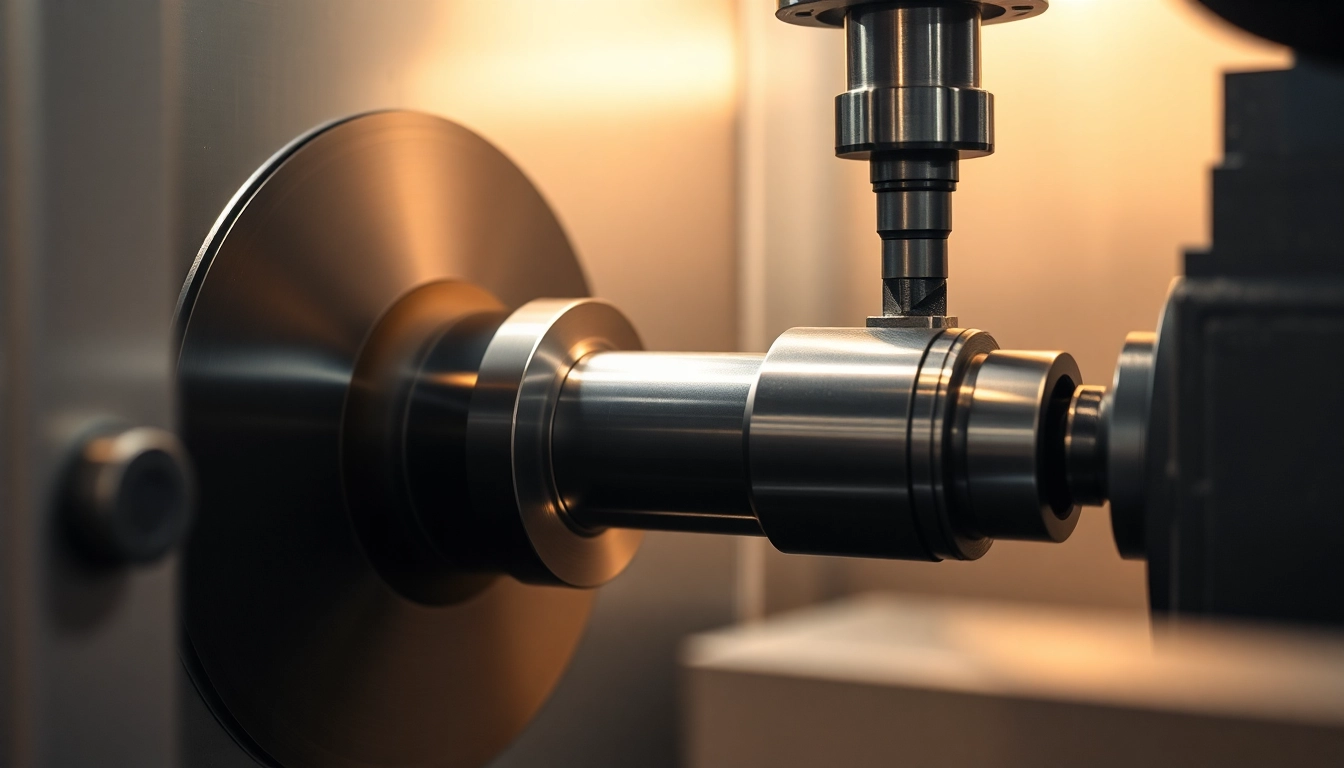

Concrete grinding involves the use of specialized machinery equipped with rotating abrasive discs or diamonds to remove surface irregularities from concrete slabs. This process smooths the surface, eliminates surface stains, and levels uneven areas, creating a uniform base for further finishing or polishing. The process typically begins with a detailed surface assessment to identify high spots, surface imperfections, or damaged areas. The grinder then systematically removes a thin layer of concrete, often measured in millimeters, depending on the desired finish. Modern concrete grinding equipment in Birmingham uses advanced technologies that optimize efficiency, minimize dust, and reduce noise, making it suitable for both commercial and residential projects.

One key aspect of concrete grinding is selecting the appropriate grit and type of abrasive segment. Coarser grits are used for heavy material removal, while finer grits prepare the surface for polishing or sealing. This precise control over material removal results in a high-quality, long-lasting finish that can be further enhanced through polishing or coating techniques.

Advantages of professional concrete grinding in Birmingham

Partnering with experienced concrete grinding specialists in Birmingham offers numerous benefits, including:

- Enhanced Aesthetics: Smooth, polished floors create a modern, professional look that adds value to commercial and residential spaces.

- Increased Durability: Removing surface imperfections and sealing the concrete can resist damage from wear, chemicals, and staining.

- Cost Efficiency: Repairing surface imperfections through grinding prevents more extensive and costly repairs in the future.

- Environmental Benefits: Professionals utilize eco-friendly equipment and techniques, reducing dust and waste, which aligns with Birmingham’s sustainability goals.

- Preparation for Additional Treatments: Properly ground surfaces are ideal for coatings, sealers, and epoxy applications, improving adhesion and longevity.

Moreover, in Birmingham’s diverse industrial and commercial sectors, concrete grinding services contribute significantly to project timelines and budgets, providing a reliable solution for maintaining high standards of floor quality.

Common applications and industries served

Concrete grinding is versatile, serving a broad spectrum of applications across industries in Birmingham:

- Industrial and manufacturing facilities: Leveling and preparing floors for new machinery or coatings.

- Commercial buildings: Creating polished, attractive flooring for retail, office, and hospitality spaces.

- Warehousing and logistics centers: Ensuring durable, smooth surfaces for safe and efficient operations.

- Residential properties: Renovating basement floors, garages, or patios with professional grinding and polishing.

- Public infrastructure and civic projects: Restoring and maintaining government buildings, schools, and community centers.

Regional contractors and service providers tailor their solutions to these varied needs, helping Birmingham’s economy thrive through durable and visually appealing concrete surfaces.

Choosing the Right Concrete Grinding Service in Birmingham

Factors to consider: experience, equipment, reputation

When selecting a concrete grinding provider in Birmingham, it’s crucial to evaluate several key factors:

- Experience and Expertise: An established contractor with a proven track record ensures quality results and professional project management.

- State-of-the-Art Equipment: Modern machinery equipped with dust collection and eco-friendly technologies enhances efficiency and safety.

- Reputation and References: Customer testimonials, online reviews, and portfolios provide insight into service quality and reliability.

- Certifications and Insurance: Proper credentials and insurance coverage protect clients and demonstrate professionalism.

In Birmingham, local companies like Concrete grinding Birmingham often stand out due to their familiarity with regional building codes, environmental considerations, and adhesion to safety standards.

How to evaluate quality and pricing

Assessing value involves balancing cost with quality. Obtain detailed quotes that include equipment used, scope of work, and project timelines. Request references or case studies demonstrating previous successful projects. Be wary of overly low bids, which may indicate subpar material use or inexperienced labor. Ideally, a reputable service provider will offer a transparent pricing structure, explain the process in detail, and guarantee satisfaction with clear terms of service.

Furthermore, explore options for ongoing maintenance packages, which can provide long-term savings and preservation of your concrete floors.

Questions to ask potential service providers

- What experience do you have with similar projects in Birmingham?

- What equipment and techniques will you use?

- Can you provide references or case studies?

- What safety measures do you employ during the grinding process?

- What warranties or guarantees do you offer on your work?

Clarifying these points ensures you select a provider committed to quality, safety, and customer satisfaction.

Best Practices for Preparing Your Property for Concrete Grinding

Site assessment and safety considerations

Proper preparation begins with a comprehensive site assessment. Ensure pathways are clear of obstructions, and identify hazardous materials like mold or deteriorated sections that may require remediation. Safety is paramount; professionals will set up barriers, provide dust control measures, and adhere to OSHA guidelines to protect workers and occupants.

Surface inspection and pre-treatment steps

Inspect the concrete surface thoroughly for cracks, loose debris, or contaminants. Repair structural damages before grinding, as unresolved issues can compromise results. Cleaning the surface with industrial vacuums or pressure washing ensures optimal adherence of sealers or coatings after grinding.

Ensuring minimal disruption and efficient process

Scheduling during off-peak hours, informing stakeholders, and coordinating logistics reduce disruptions. Using advanced dust extraction systems and efficient equipment accelerates project timelines. Clear communication about the process, estimated duration, and post-project cleanup enhances overall satisfaction.

Implementing Concrete Grinding for Long-Term Durability and Aesthetics

Finishing techniques: polishing, sealing, and coating

Post-grinding, applying polishing techniques amplifies the concrete’s gloss and smoothness, creating an attractive, high-end finish. Sealing enhances stain resistance, reduces dust, and protects against moisture ingress. Epoxy or polyurethane coatings can further strengthen surfaces and customize appearance, especially in industrial or commercial settings.

Maintaining your concrete floors post-grinding

Regular cleaning with non-abrasive methods, prompt spill cleanup, and periodic resealing maintain the aesthetic appeal and durability of your floors. Avoid harsh chemicals or abrasive scrubbers that can damage the sealant or surface. Scheduling routine inspections ensures early detection of wear or damage, allowing timely intervention.

Measuring success: performance and client satisfaction

Success is reflected in the durability, appearance, and functionality of the finished floors. Feedback from clients, visual inspections, and surface testing for smoothness and stain resistance are standard measures. Long-term performance data validate the quality of the grinding process and guide future projects.

Trending Technologies and Innovations in Birmingham Concrete Grinding

Advanced equipment for precision and efficiency

The advent of robotic grinders, multi-head machines, and automated dust extraction systems has revolutionized concrete grinding. These tools allow for faster, more precise finishes, reducing labor costs and ensuring consistent quality—critical advantages for Birmingham’s growing construction market.

Eco-friendly and sustainable grinding solutions

Sustainable practices include the use of eco-friendly abrasives, energy-efficient machinery, and dust suppression technologies. These innovations minimize environmental impact and align with Birmingham’s initiatives toward greener urban development.

Case studies of recent successful projects

Recent Birmingham projects showcase the latest innovations: for example, a commercial showroom received a high-gloss polished finish using diamond grinding equipment combined with eco-friendly sealers, resulting in a durable and visually stunning surface that attracted premium tenants. These case studies reinforce the importance of technological integration for outstanding results.